Tailings problem, gold companies to solve this way ......

Jun 29, 2023

Tailings problem, gold companies to solve this way ......

Jun 29, 2023

Tailings problem, gold companies to solve this way ......

Tailings usually refers to mine solid waste that is not suitable for further sorting and recovery under the prevailing conditions after mine beneficiation. And tailings storage simply refers to the construction of a dam to intercept the valley mouth or enclose the land constituted to stockpile metal or non-metallic mines for ore beneficiation after the discharge of tailings or other industrial waste places.

At present, there are nearly 10,000 tailing ponds in China, and the number of tailing ponds is large and widely distributed. Tailings pond environmental management base is weak, coupled with the tailings pond pollution hidden strong, some tailings ponds adjacent to important rivers, drinking water sources and other ecologically sensitive targets, pollution prevention measures are not perfect, operation and management is not standardized, environmental risks are more prominent.

Tailings pollution problem should not be underestimated

The problem of tailings is extremely prominent in the mining pollution problems that have occurred in recent years.

The 2011 Yunnan Qujing chrome slag pollution incident, resulting in the death of sheep, pigs and undrinkable water;

a mining company in Shaanxi Province in 2012 discharged ore processing slag through a river berm, affecting the arable land of downstream villages and the lives and property of residents;

2015, a company located in Longnan City tailings pond leakage, resulting in a sudden environmental incident across Gansu, Shaanxi and Sichuan provinces, causing a certain impact on the production and living water of some people along the line, and directly threatening the safety of water supply to local residents;

In 2020, a mining company tailings pond in Heilongjiang Province leaked, causing the local first water plant to stop taking water, and some river sections, farmland and woodland pollution in Yichun City and Suihua City ......

These lessons always remind us that the pollution problem caused by tailings cannot be underestimated and must be taken seriously.

The Law of the People's Republic of China on Environmental Prevention and Control of Solid Waste Pollution (amended in 2020) requires that adhering to the principles of reduction, resourcefulness and harmlessness, mining enterprises should adopt scientific mining methods and beneficiation processes to reduce the amount of tailings, coal gangue, waste rock and other mining solid waste generated and stored. At the same time, the state encourages the adoption of advanced technology for tailings, coal gangue, waste rock and other mining solid waste for comprehensive utilization. Tailings, coal gangue, waste rock and other mining solid waste storage facilities after the cessation of use, mining enterprises should be sealed in accordance with national regulations on environmental protection and other provisions to prevent environmental pollution and ecological damage.

In 2022, the Ministry of Ecology and Environment issued the "tailings pollution prevention and management measures," "tailings pond pollution hidden danger investigation and management technical guidelines (for trial implementation)" to risk prevention and control as the core implementation of tailings pond classification and classification of environmental management, and firmly guard the bottom line of ecological and environmental security. At the same time continue to promote the Yangtze River economic belt, the Yellow River basin and other key areas, watershed tailing pond pollution management, strengthen the flood tailing pond pollution hidden danger investigation and management, and improve the tailing pond environmental supervision infrastructure capacity, further improve the tailing pond environmental information, build tailing pond environmental management information system, with information technology means to enhance the tailing pond environmental management capacity and level, enhance the ecological environment departments around the tailing pond Pollution management level and environmental supervision capacity.

And the World Gold Council also reflects the high importance it places on tailings and emissions management in its 2019 release of the Responsible Gold Mining Principles (RGMP) - we will ensure that environmental responsibility is at the heart of our operations and will follow ongoing management and governance actions that are consistent with accepted practices to design, construct, manage and abandoned tailings storage and heap leach facilities and major hydraulic infrastructure. At the same time, no new mines will be developed that would involve the use of riverine or shallow seabed tailings.

Managing tailings gold companies have been taking action

For gold mining companies, the concern for ecological protection and the practice of the concept of "green water and green mountain is the silver mountain" is something that they need to improve and implement throughout their production management process. Many gold mining companies have been exploring and taking concrete actions to address the core issue of tailings management.

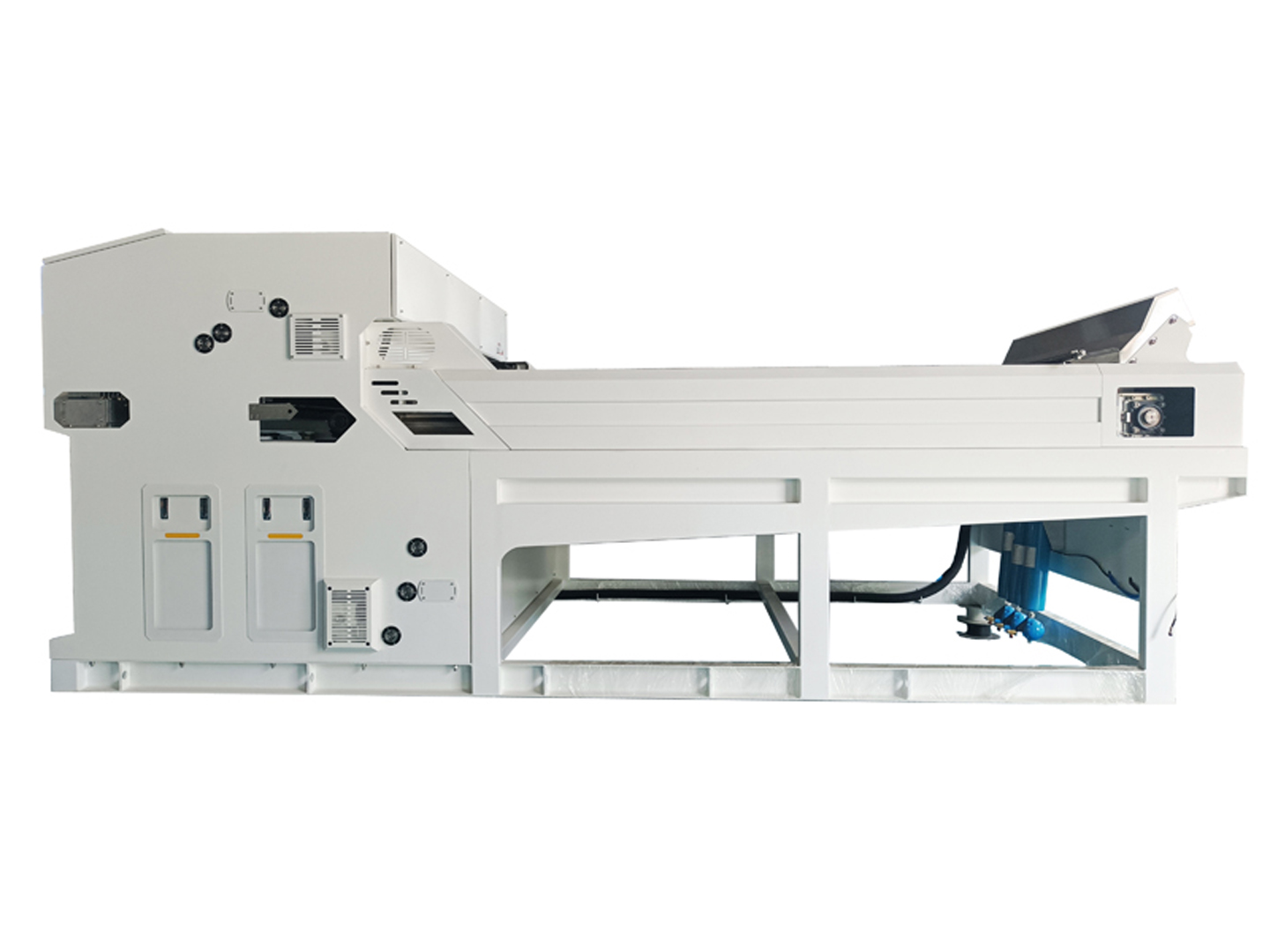

In order to improve the tailings problem in the mining process, many enterprises use advanced AI ore sorting machine to enrich the tailings, enhance the grade of ore and reduce the tailings throwing.

In order to improve the tailings problem in the mining process, many gold mining companies have adopted dust prevention and environmentally friendly mining methods. For example, in order to manage the adverse effects brought by tailings, all subsidiaries of China Gold Group have hardened or greened the exposed ground of industrial sites, and set up wind and dust suppression nets in the tailings storage and coal pile of the boiler house, equipped with watering trucks, and regularly sprinkled the site road surface, ore transportation road and tailings storage, which effectively reduce dust pollution.

Ltd. as a tailing-free metal mine is implementing the filling method of mining, most of the tailing sand is used to fill the underground mining area, and the composition of the remaining tailing sand is tested, combined with the characteristics of tailing sand with high calcium content, small particles, easy to form, and high pressure resistance after drying, and actively cooperates with local cement plants and brick kiln factories, and part of it is supplied to relevant enterprises in proportion to maximize the value of the effective use of mineral resources. .

The comprehensive utilization of tailings and waste rocks is another practice of gold mining enterprises to explore tailings management. For example, Zijin Mining Group has always given priority to the comprehensive utilization of tailings and waste rocks by means of underground filling, use as construction materials, vegetation restoration, road paving and recovery of valuable components, etc. The rest is stockpiled in drainage sites or tailing ponds that meet the national standards of the location, and the tailing ponds are impermeable in accordance with the requirements of the local standards to ensure the safety of groundwater quality downstream of the tailing ponds. The Group strictly follows the approved design plan for the operation of re-mining, sand discharge and drainage in the reservoir to ensure the safety of the tailing dam and the original flood discharge facilities, and conducts inspection and facility maintenance management in accordance with the relevant requirements of tailing pond safety management. After all the tailings back mining no longer carry out tailing operations, timely to the safety production supervision and management departments to fulfill the tailing pond cancellation procedures. At the same time, the tailing pond will be closed according to the regulations of tailing pond closure after the reuse production is completed.

In addition, Anhui Taiping Mining Co., Ltd, a subsidiary of China Gold Group, also provides tailings sand after physical drying to road construction enterprises as raw materials, opening up a new way of mineral resources development and comprehensive utilization, which not only saves resources, but also provides a broader space for the company to expand the comprehensive utilization of tailings sand.

Only by improving the utilization rate of water resources and protecting water resources can we achieve the long-term and stable development of gold mining enterprises. The recycling of water resources has also become a major direction for gold mining enterprises in the management of tailings. In China Gold Group, most of the mining enterprises adopt the tailing slag press filter dry discharge technology, adopt press filter dry discharge for tailing, and recycle water resources, all wastewater is not discharged, and the water recycling rate reaches more than 92%. For example, after the tailing wastewater is clarified and treated, it flows into the return dam under the tailing reservoir and is pumped back to the high level pool of the processing plant for flotation production recycling, and the water in the tailing reservoir is not discharged.

In addition, Tong Hui Mining, a subsidiary of Zhajin Mining, has invested more than 6 million yuan to build a tailing wastewater recycling system and an underground mine brine water recycling system, and laid a wastewater recycling and reuse pipeline, so that all the recycled wastewater can be used for production reuse after treatment, which can reduce the amount of new water used for ore dressing by more than 2 million cubic meters per year and realize the efficient recycling of ore dressing wastewater. Zero discharge" and 100% "reuse" of saline water under the mine, ensuring the coordinated development and green development of the production system and the ecosystem. For the tailing sand produced by the beneficiation plant, Tong Hui Mining actively carries out project research and development, using the tailing sand to carry out the paste cement filling project, filling more than 70% of the tailing sand into the underground mining area and the former surface collapse area after thickening, reducing the amount of tailing sand discharge, effectively extending the service life of the tailing pond, and generating good social and ecological benefits.

In addition to tailings management in the mining process, gold mining enterprises are also exploring and practicing in pre-mining assessment and post-operation ecological restoration. Before the construction of each project, Zhaogold Mining Co., Ltd. conducts environmental impact assessment in strict accordance with the procedures, analyzes the possible impact on the environment after the project is completed and put into operation, and proposes countermeasures and measures to prevent pollution. At the same time, Zhaogold Mining, in addition to conscientiously fulfilling the procedures of environmental protection acceptance of project completion, carries out comprehensive recycling of the waste left behind in the production process, focuses on strengthening the comprehensive management of mining areas and tailing ponds, and does a good job of mine greening, beautification and ecological environment construction to further improve the environmental situation around the enterprise.

In February this year, Serbia's Zijin Copper Boer River comprehensive environmental management project officially dug into the construction. After the completion of the project will enhance the tailings storage and open pit safety operation capacity, improve the ecological environment of the natural water system in the downstream section of the Pol River and Timok (Timok), with good ecological and social benefits. Zijin Por copper mine insists on creating a "garden mine" and vigorously implements greening and reclamation. At present, all tailing ponds, open pit slopes and slopes of some abandoned dumps have been greened, with more than 60,000 seedlings planted and a new greening area of about 350,000 square meters, giving the mine and plant areas a new look. The project has also taken many measures to control dust, solid waste, waste water and waste gas, with remarkable results.

In addition, some gold mining enterprises have also built a model combining "industry, academia and research" to promote tailings management.

For example, Shandong Gold Group, in view of the common problems such as the high emission of gold tailings and the high disposal cost and safety and environmental protection pressure caused by the residual cyanide in the smelting cyanide slag, has organized relevant enterprises and strong scientific research institutes in China to jointly establish the "Joint Innovation Research Base for Resourceful Utilization of Gold Tailings", with the theme of low-cost resourceful disposal of gold tailings. Low-cost resource utilization disposal is the theme, using AI ore sorting machine ,Mineral separator , bulk ore sorting system and optical sorting machine to enrich the grade ,reducing the tailing, giving full play to the advantages of internal and external resources, to overcome the key technology of resource utilization of tailings, to build a demonstration project of ecological disposal of tailings, and to solve the problem of "neck" of tailings disposal.

The waste stone is widely used for underground filling, tailing reservoir dam building, building stone, etc. The tailing sand is comprehensively used for underground filling, outbound transportation, construction materials, etc. The comprehensive disposal rate of tailing sand is greatly improved. Among them, Xinhui Company and Hainan Shanjin Company took the lead in building a tailing-free mine, realizing comprehensive recycling and turning waste into treasure, and its advanced experience and practices are being promoted and applied in other mines. At the same time to strengthen the whole process of standardized management of hazardous waste, the enterprises belong to the establishment of standardized hazardous waste temporary storage room, the strict implementation of the five-linked list system, to achieve the collection, utilization, temporary storage, transportation, utilization and disposal of hazardous waste for the whole process of standardized management.

How phosphate ore is enriched by beneficiation

Nov 03, 2022

How phosphate ore is enriched by beneficiation

Nov 03, 2022

How to choose ore color sorter?

Nov 24, 2022

How to choose ore color sorter?

Nov 24, 2022

Long life of Mineral separator should be maintained routinely

Dec 07, 2022

Long life of Mineral separator should be maintained routinely

Dec 07, 2022

Tailings problem, gold companies to solve this way ......

Jun 29, 2023

Tailings problem, gold companies to solve this way ......

Jun 29, 2023

Introduction of Phosphate Ore

Jun 08, 2024

Introduction of Phosphate Ore

Jun 08, 2024

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

Application of Photoelectric Ore Separation Technology in Low-Grade Ore Resource Processing

Jun 29, 2024

Application of Photoelectric Ore Separation Technology in Low-Grade Ore Resource Processing

Jun 29, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

How to Sort Wollastonite?

Jul 20, 2024

How to Sort Wollastonite?

Jul 20, 2024

AI intelligent Sorting Machine: A New Choice for Ore Sorting

Jul 20, 2024

AI intelligent Sorting Machine: A New Choice for Ore Sorting

Jul 20, 2024

Comprehensive Analysis of X-ray Intelligent Ore Sorting Machine

Jul 27, 2024

Comprehensive Analysis of X-ray Intelligent Ore Sorting Machine

Jul 27, 2024