Classification, Uses and Sorting Processes of Various Types of Ores!

Jun 08, 2024

Classification, Uses and Sorting Processes of Various Types of Ores!

Jun 08, 2024

The classification and use of ores are very wide. We classify them based on many factors such as the chemical composition, physical properties and industrial applications of minerals. The following are the types of metal ores and non-metallic ores that can be roughly sorted.

Metal ore

Metal ores are ores containing metal elements or metal compounds, and are mainly used to extract metals. Depending on the metals they contain, metal ores can be subdivided into the following categories:

1. Precious metal ores: such as gold, silver, platinum group metal ores, etc., are mainly used in the manufacture of jewelry, currency reserves and some high-tech products.

2. Non-ferrous metal ores: including copper, lead, zinc, aluminum, etc., which are widely used in wires and cables, building materials, automobile manufacturing, aircraft manufacturing, electronic products and other fields.

3. Ferrous metal ores: such as iron ore, manganese ore, and chromium ore, which are mainly used in the production of steel and other alloys.

4. Rare metal ores: such as tantalum, niobium, lithium, etc., are crucial to high-tech industries such as electronics, aerospace, and new energy vehicles.

5. Radioactive ores: such as uranium ore and thorium ore, which are mainly used in nuclear power generation and medical fields.

After mining, crushing, beneficiation and refining, these ores can be refined into metals, which are processed into various products and widely used in various industries such as construction, machinery manufacturing, electronics, transportation, aerospace, etc.

Non-metallic ores

Non-metallic ores contain no or almost no metal elements. They either provide industrial raw materials or are used as decorative and building materials.

1. Chemical raw material ores: such as phosphate rock, potash, limestone, etc., used in the manufacture of fertilizers and chemical products.

2. Gemstones and decorative stones: such as diamonds, rubies, jade, marble, granite, etc., used in jewelry and architectural decoration.

3. Building material ores: such as gypsum, quartz sand, and limestone, used in cement, glass manufacturing and the construction industry.

4. Ceramic and refractory ores: such as kaolin and clay, used to make ceramic utensils and high-temperature resistant materials.

5. Energy minerals: such as coal, oil, and natural gas. Although they do not strictly belong to the traditional mineral classification, they are also important natural resources and are mainly used for energy supply.

In addition to being used as a building material, it is also used to manufacture chemicals, medicines, cosmetics, ceramic products, glass products, etc. It is also widely used in agriculture, environmental protection and high-tech industries.

In summary, ores are various and have a wide range of uses. From metal ores to non-metallic ores, from energy ores to construction ores and chemical raw material ores, they all play an important role in their respective fields. The mining and utilization of ores is one of the foundations of modern industrial society. However, the mining process needs to consider environmental protection and sustainable development. With the advancement of science and technology and the development of industry, human demand for ores will continue to increase, and the mining and utilization of ores will become more efficient and environmentally friendly.

In order to make full use of various metal and non-metallic ore resources, suitable mineral processing technology is selected for separation in combination with the physical and chemical characteristics of the ore. At present, the common mineral processing methods are mainly the following:

Flotation: It is a method of separation by treating the physical and chemical properties of the ore surface to make the minerals selectively attach to bubbles. In the process of mineral processing, especially in the treatment of non-ferrous metal ores (such as copper, lead, zinc, sulfur, molybdenum, etc.), flotation is widely used. In addition, some ferrous metals, rare metals and non-metallic ores (such as graphite ore, apatite, etc.) can also be treated by flotation.

Gravity separation: It is a method of separation based on the relative density (also called specific gravity) of minerals. By applying fluid dynamics and various mechanical forces in a moving medium (such as water or air), the concentrators of different densities can create suitable loose stratification and separation conditions, thereby achieving the separation of mineral particles of different densities.

Magnetic separation: It is a method of separating ores by using the magnetic difference of minerals to generate different forces in the magnetic field of the magnetic separator. It is mainly used for the separation of ferrous metal ores (such as iron, manganese, and chromium), and can also be used for the separation of non-ferrous metal and rare metal ores.

Electrostatic separation: It is a separation method based on the difference in the electrical conductivity of minerals. By placing the minerals in a high-voltage electric field, the electrostatic force acts differently due to the different electrical conductivity of the minerals, thereby achieving the separation of minerals. This method is mainly used for the separation of rare metals, non-ferrous metals and non-metallic ores, especially in the separation of sub-mixed coarse concentrates, such as scheelite and cassiterite, zircon, tantalite and niobium ore.

Chemical beneficiation: It is a beneficiation technology that uses chemical methods to change the mineral composition and then enriches the target components through other methods. For example, copper ore containing malachite can be leached with dilute sulfuric acid to convert malachite into copper sulfate solution. By replacing the copper ions in the solution with iron filings, metallic copper (sponge copper) can be obtained. Chemical beneficiation is one of the effective methods for processing and comprehensively utilizing some poor, fine, and impure mineral raw materials that are difficult to be selected. It is also one of the important ways to make full use of mineral resources, solve the problems of wastewater, waste residue, and waste gas treatment, realize waste recycling, and protect the environment.

Microbial beneficiation: also known as bacterial beneficiation, is a beneficiation method that uses microorganisms such as iron-oxidizing bacteria, sulfur-oxidizing bacteria, and silicate bacteria to remove iron, sulfur, silicon and other elements from ores. By using iron-oxidizing bacteria to oxidize iron, sulfur-oxidizing bacteria to oxidize sulfur, and silicate bacteria to decompose silicon in bauxite, the purpose of desulfurization, iron removal and silicon removal can be achieved. In addition, microbial beneficiation can also be used to recover metals such as copper, uranium, cobalt, manganese, and gold.

https://www.mdoresorting.com/mingde-ai-sorting-machine-separate-phosphorite-ore

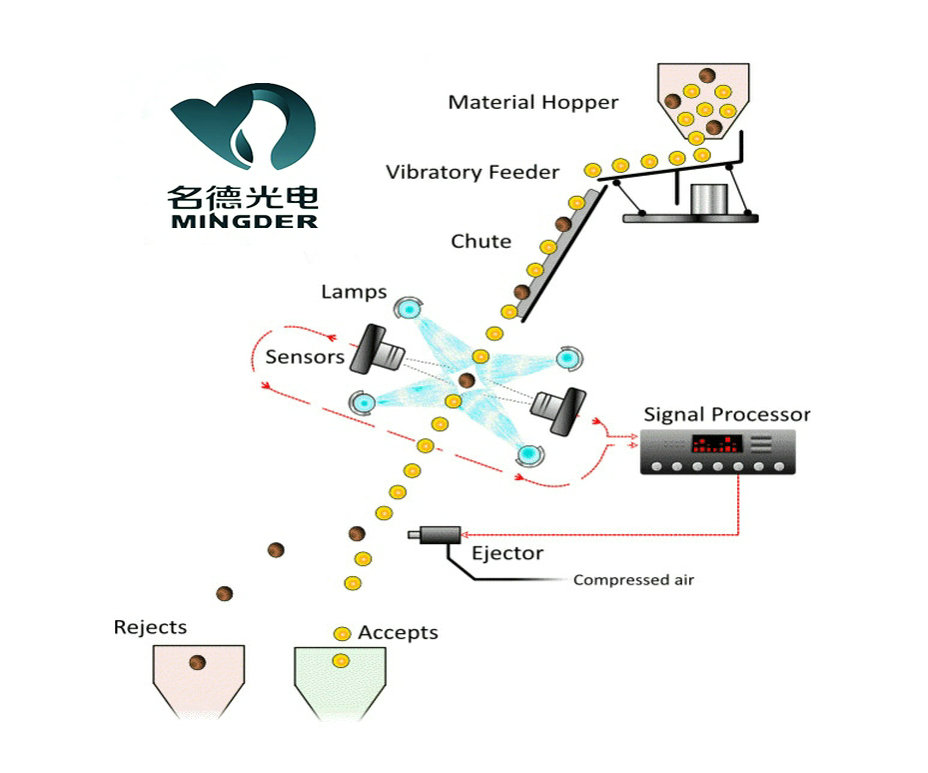

Photoelectric beneficiation: It is a beneficiation method that uses the physical characteristics of the ore to be beneficiated and the gangue to identify and sort. It uses a combination of machinery and electricity to separate minerals by imitating the action of hand selection. It uses the differences in the reflection and transmittance of light of different minerals, such as color, texture, shape, gloss, spots, density and other characteristic differences for identification and sorting. The ore is mainly separated after passing through the feeding system, photoelectric system, electric control system and sorting system.

As a leader in the photoelectric mineral processing industry, Mingde Optoelectronics has launched a series of equipment, involving five series and more than 20 types of equipment, mainly artificial intelligence sorting machines, ore color sorting machines, mineral sand sorting machines, X-ray intelligent sorting machines, foreign body removal robots and other products. At present, it is widely used in metal and non-metallic minerals such as quartz, potassium feldspar, calcite, calcium carbonate, dolomite, fluorite, talc, wollastonite, bauxite, pegmatite quartz, limestone, calcium oxide, sponge titanium, silicon slag, gold mine, pebbles, phosphate rock, silica, brucite, tungsten tailings, coal gangue, coal-bearing kaolin, etc.!

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

What's an Ore Sorter: Introducing Mining's Advanced Sorting Technologies

Nov 11, 2023

Do You Really Know about Feldspar?

May 18, 2024

Do You Really Know about Feldspar?

May 18, 2024

Classification, Uses and Sorting Processes of Various Types of Ores!

Jun 08, 2024

Classification, Uses and Sorting Processes of Various Types of Ores!

Jun 08, 2024

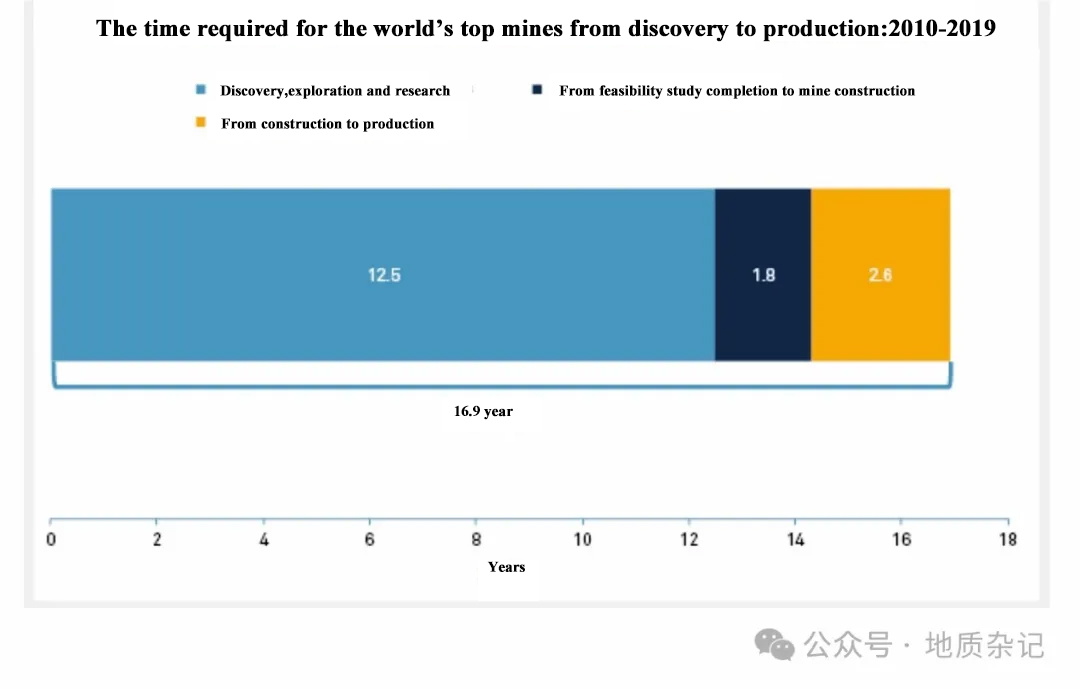

The Average Time Required for the World's Top Mines from Discovery to Production is 16.9 Years

Jun 25, 2024

The Average Time Required for the World's Top Mines from Discovery to Production is 16.9 Years

Jun 25, 2024

Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

Brucite: Characteristics, Distribution, Uses and Beneficiation Methods!

Jun 29, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

The Importance of Ore Pretreatment and Enrichment

Jul 13, 2024

The Importance of Ore Pretreatment and Enrichment

Jul 13, 2024

Photoelectric Sorting of Titanium Sponge

Jul 13, 2024

Photoelectric Sorting of Titanium Sponge

Jul 13, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

Practical Application and Separation of Potassium Feldspar

Jul 20, 2024

How to Sort Wollastonite?

Jul 20, 2024

How to Sort Wollastonite?

Jul 20, 2024

The Significance of Ore "Dissociation Degree", "Over-Crushing" and Pre-sorting!

Jul 27, 2024

The Significance of Ore "Dissociation Degree", "Over-Crushing" and Pre-sorting!

Jul 27, 2024