Causes and Solutions Affecting Low Efficiency of Mineral Processing!

May 31, 2024

Causes and Solutions Affecting Low Efficiency of Mineral Processing!

May 31, 2024

1. Which links in the mineral processing process are likely to affect efficiency?

In the mineral processing technology, multiple links may affect the mineral processing efficiency, and the following links are more likely to have a significant impact on the mineral processing efficiency:

(1) Pre-election preparation stage:

Crushing and Screening:

Ore crushing and screening are key steps before mineral processing, which directly affect the efficiency and effect of subsequent mineral processing. In the crushing operation, if the crusher is improperly selected or operated, it may lead to insufficient or excessive crushing of the ore, affecting the efficiency of subsequent grinding and mineral processing. Screening is used to classify the crushed ore according to particle size to provide suitable raw materials for the processing.

Grinding and Classification:

Grinding is the continuation of the ore crushing process, and its purpose is to separate various useful mineral particles in the ore into monomers for selection. The selection of grinding mills and the control of the grinding process are crucial to the efficiency of mineral processing. The classification operation affects the classification particle size and processing capacity by adjusting parameters such as the size of the classification area, the height of the overflow weir and the speed of the spiral, thereby affecting the efficiency of mineral processing.

Selection stage:

The properties of the ore, the selection of the beneficiation equipment and the selection of the beneficiation method will affect the efficiency of the beneficiation stage. For example, the particle size of the mineral has an important influence on the flotation efficiency. Too fine a particle size will deteriorate the flotation effect. The selection of the flotation machine speed will also affect the stirring intensity of the slurry and the flotation effect.

Dehydration stage after selection:

The concentrate obtained by wet beneficiation usually contains a lot of water. The efficiency of the dehydration stage directly affects the quality and output of the concentrate. The dehydration stage includes processes such as concentration, filtration and drying. The effects of these processes are affected by factors such as equipment performance, operation level and the properties of the original ore.

Slurry concentration:

Appropriate pulp concentration has an important impact on flotation efficiency. Within a certain range, increasing pulp concentration is conducive to the collision and contact between minerals and reagents, thereby improving flotation efficiency. However, excessive pulp concentration will increase reagent consumption, deteriorate aeration effect, and reduce flotation efficiency.

Operation and management:

The skill level and management level of operators also have an important impact on mineral processing efficiency. Modern and digital management methods can optimize the mineral processing process and improve production efficiency. At the same time, strengthening the management and awareness of mining companies and avoiding management and awareness deviations are also important measures to improve mineral processing efficiency.

To sum up, many links in the mineral processing process may affect the efficiency, but factors such as the preparation stage before mineral processing, the separation stage, the dehydration stage after mineral processing, as well as slurry concentration and operation management have the most significant impact on mineral processing efficiency. By optimizing these links and factors, the mineral processing efficiency can be significantly improved, production costs can be reduced, and the sustainable development of the mine can be achieved.

2. In order to optimize the links that affect efficiency in the mineral processing process, we can consider and implement them from the following aspects:

(1) Grinding and grading operations:

Optimize grinding process parameters: According to the characteristics of the ore, study the grinding index and formulate appropriate grinding process parameters. For the ore dressing plant with "over-grinding" phenomenon, selective grinding technology can be considered.

Use efficient grading equipment: Although spiral classifiers are commonly used, their grading efficiency is generally only 20% to 40%. Consider introducing efficient grading equipment such as hydrocyclones or high-frequency vibrating fine screens to improve grading efficiency. However, attention should be paid to the stability of hydrocyclones.

(2) Selection of work:

Select or improve mineral processing equipment: In flotation operations, the selection of flotation machines is crucial. According to the characteristics of the ore and the flotation process, select or design a suitable flotation machine. At the same time, pay attention to the development of flotation reagents and processes, and adopt the latest flotation technology and reagents.

Optimize flotation conditions: According to the properties of the ore, adjust the parameters such as pulp concentration, stirring intensity, and aeration volume during the flotation process to obtain the best flotation effect.

(3) Dehydration operation:

Introduce advanced dehydration equipment: such as disc vacuum filter, which not only has large processing capacity and good dehydration effect, but also has low energy consumption.

Optimize the dehydration process: By adjusting various links in the dehydration process, such as pre-dehydration, filter pressing, etc., the dehydration efficiency can be improved and the moisture content in the concentrate can be reduced.

(4) Slurry concentration control:

Real-time monitoring and adjustment: By real-time monitoring of pulp concentration, timely adjust the amount of water added during grinding and flotation to ensure that the pulp concentration is within the optimal range.

Optimize the use of reagents: During the flotation process, adjust the amount and type of reagents according to the pulp concentration to obtain the best flotation effect.

(5) Operation and management:

Improve operator skills: Through training and skill improvement, ensure that operators have the necessary mineral processing knowledge and skills and can operate mineral processing equipment proficiently.

Introduce a modern management system: Use a digital and automated management system to monitor all aspects of the mineral processing process in real time to improve production efficiency and product quality.

Strictly follow the principles of comprehensiveness and pertinence to carry out equipment transformation to ensure that the transformation work can truly improve economic benefits and production efficiency.

(6) Strengthen the management of mining companies:

Correct the deviations in the management and cognition of mining companies, ensure that managers have geological knowledge and mineral processing experience, and avoid non-geological personnel from conducting mineral processing according to the management model of other industries.

Establish a reasonable assessment mechanism, avoid taking economic benefits as the only criterion, and ensure that the basic status of geological exploration work is valued.

Through the implementation of the above measures, the links that affect efficiency in the mineral processing process can be optimized, the mineral processing efficiency can be improved, the production cost can be reduced, and the sustainable development of the mine can be achieved.

(7) Continuous research and innovation:

Encourage and support scientific researchers to conduct research and innovation in mineral processing technology, and continuously develop new mineral processing methods and processes. Strengthen exchanges and cooperation with other countries and regions, and introduce advanced mineral processing technology and equipment.

At the same time, in view of the above-mentioned problem of low mineral processing efficiency, the introduction of MINGDE mineral processing equipment can greatly improve the mineral processing efficiency. Its value is mainly reflected in the following aspects:

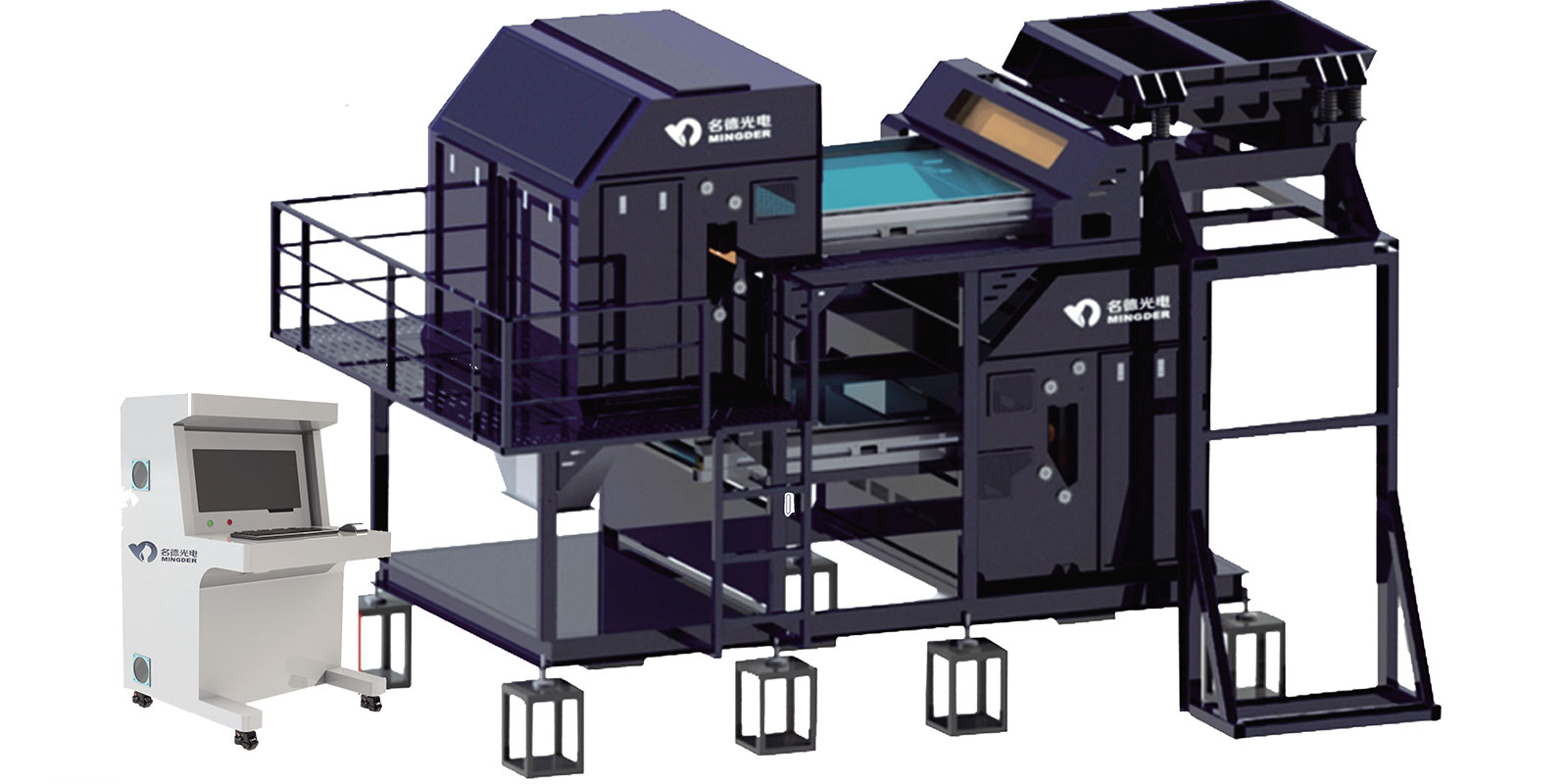

High-precision identification and sorting:

MINGDE optoelectronic beneficiation equipment, such as the MINGDE AI sorter, can accurately identify multiple characteristics of non-metallic ores, including color, texture, shape, gloss, etc. This high-precision recognition technology enables ores to be accurately classified and screened, thereby improving the accuracy and efficiency of beneficiation.

High efficiency sorting:

The equipment has high-speed processing capabilities and can quickly complete the sorting of a large number of non-metallic ores. For example, the heavy-duty visible light artificial intelligence sorting machine product launched by MINGDE Optoelectronic has a sorting and processing capacity of up to 100 tons/hour, greatly improving production efficiency.

Energy saving:

MINGDE Optoelectronic mineral processing equipment achieves more crushing and less grinding by pre-sorting the granular ore, effectively reducing energy consumption. This optimization can not only improve production efficiency, but also reduce mineral processing costs and improve the economic and ecological benefits of the mineral processing plant.

Environmental friendly:

Compared with traditional physical and chemical beneficiation, the only energy consumption of photoelectric beneficiation is electricity consumption, and it has zero pollution to the environment. This green beneficiation method meets the current requirements of environmental protection and contributes to the sustainable development of mining production.

High level of intelligence:

With the development of computer technology and artificial intelligence technology, the intelligence level of Mingde Optoelectronics' mineral processing equipment has been continuously improved. This intelligent equipment can better adapt to the sorting needs of different types and complex ore structures, and improve the flexibility and adaptability of mineral processing.

In summary, Mingde Optoelectronics' mineral processing equipment provides strong support for improving mineral processing efficiency through its advantages in high-precision identification, high-efficiency sorting, energy saving and consumption reduction, green environmental protection and high intelligence level. These advantages not only help to improve the efficiency and benefits of mining production, but also help to promote the green, intelligent and sustainable development of mining production.

Indian Delegation Gains Insights into MINGDE’s AI-driven Ore Sorting

May 15, 2024

Indian Delegation Gains Insights into MINGDE’s AI-driven Ore Sorting

May 15, 2024

Do You Really Know about Feldspar?

May 18, 2024

Do You Really Know about Feldspar?

May 18, 2024

Causes and Solutions Affecting Low Efficiency of Mineral Processing!

May 31, 2024

Causes and Solutions Affecting Low Efficiency of Mineral Processing!

May 31, 2024

Application and Advantages of MINGDE AI Sorter in Non-metallic Ores

Jun 03, 2024

Application and Advantages of MINGDE AI Sorter in Non-metallic Ores

Jun 03, 2024

What are the Specific Application Scenarios of AI Technology in Mining Resource Sorting?

Jun 11, 2024

What are the Specific Application Scenarios of AI Technology in Mining Resource Sorting?

Jun 11, 2024

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

What are the Factors that Affect Ore Sorting?

Jun 12, 2024

An Article on Limestone

Jun 14, 2024

An Article on Limestone

Jun 14, 2024

A Detailed Introduction to Talc

Jun 22, 2024

A Detailed Introduction to Talc

Jun 22, 2024

Application of Photoelectric Ore Separation Technology in Low-Grade Ore Resource Processing

Jun 29, 2024

Application of Photoelectric Ore Separation Technology in Low-Grade Ore Resource Processing

Jun 29, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

Specific Applications and Future Prospects of Photoelectric Sorting Technology

Jul 03, 2024

Photoelectric Sorting of Titanium Sponge

Jul 13, 2024

Photoelectric Sorting of Titanium Sponge

Jul 13, 2024

Sorting and Application of Silica Ore

Jul 16, 2024

Sorting and Application of Silica Ore

Jul 16, 2024