Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

Tags :

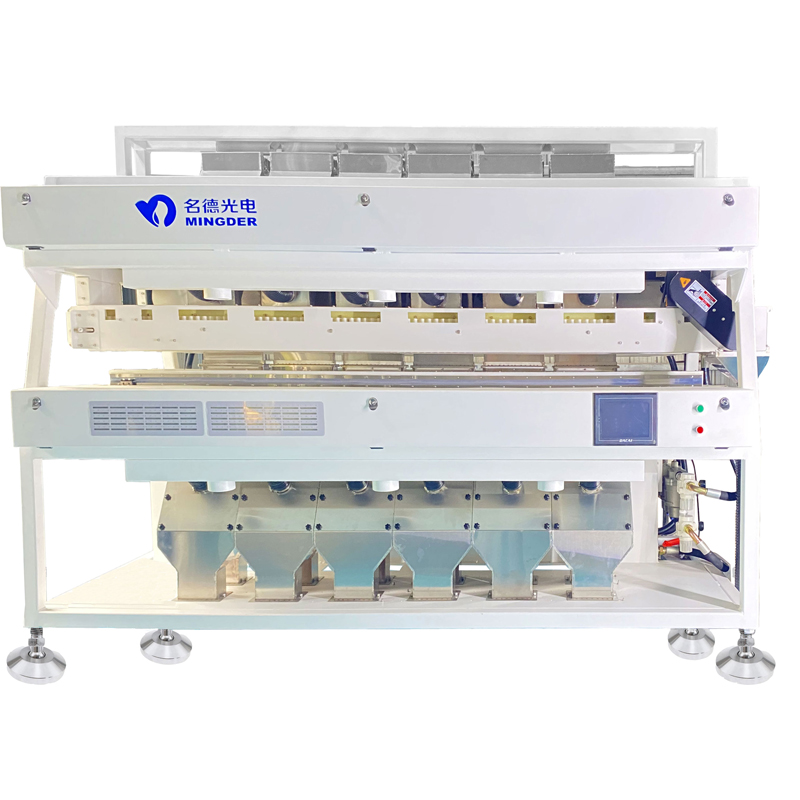

Mingde Optoelectronics artificial intelligence sorting equipment take the lead in

introducing artificial intelligence methods such as deep convolutional neural networks

(CNN) in the field of visible light photoelectric sorting to analyze and process material

images,and through CNN partial connection, weight sharing, multiple convolution

kernels and other methods ,during the training process, the multi-dimensional features

of materials are automatically extracted to establish a database, whose sorting effect is

far better than traditional photoelectric methods.