In the process of mining and transportation, ores are often mixed with wood, steel nails, rags, plastic parts, waste filling pipes and other sundries. These sundries has seriously affected the safety and effectiveness of equipment in the transportation, crushing, grinding and beneficiation . In the past, manual sorting was usually used to remove it, but there are serious safety and occupational health risks in manual sorting, as well as problems such as incomplete manual sorting. The robot for mining can effectively solve the above problems.

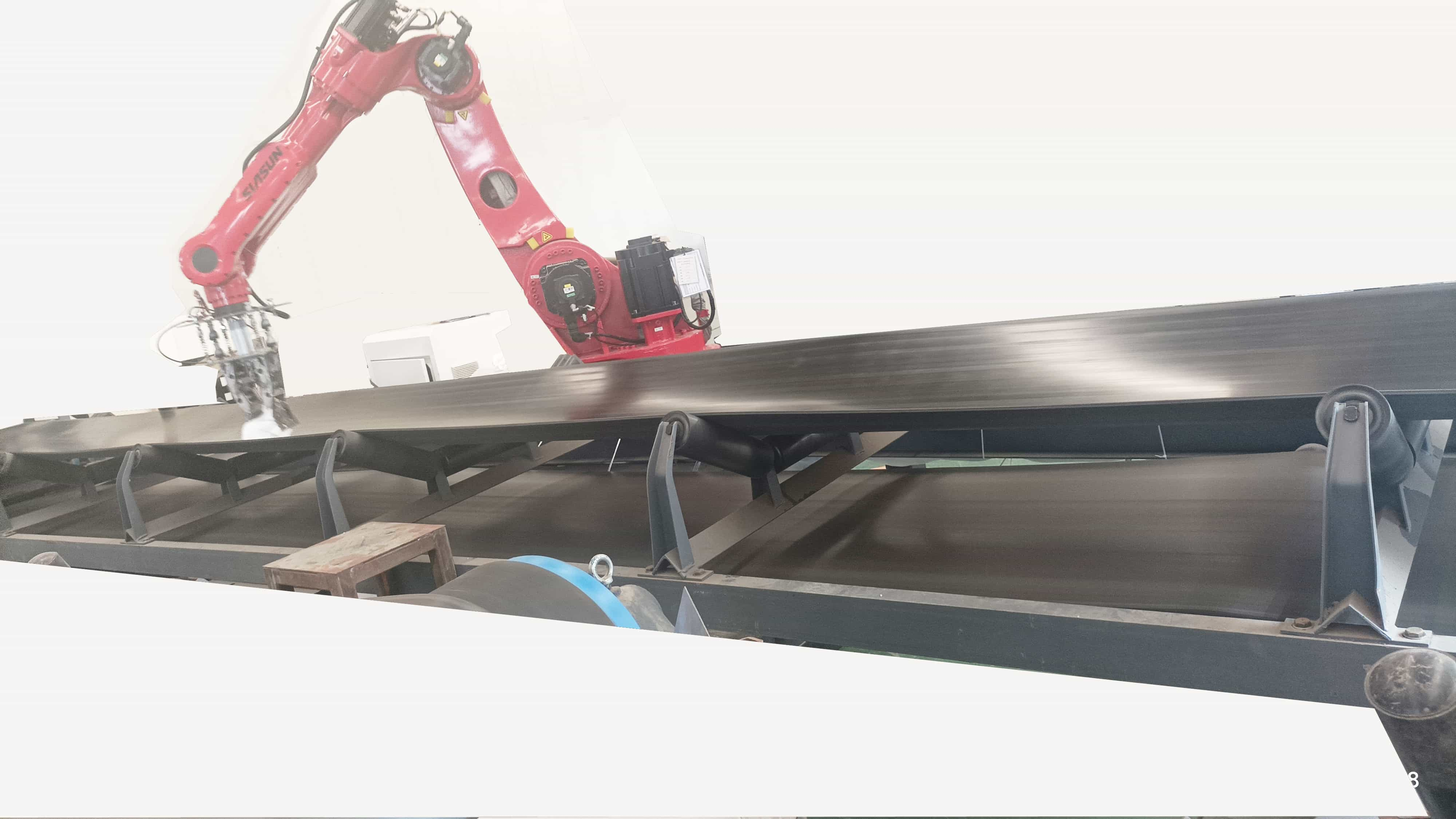

Mingde 6 axis industrial manipulator Material Removal Robot Foreign Body Exclusion Robot Robotic Manipulator Robot Arm

Mingde Foreign object removal robot remove sundries from Ores In the process of mining and transportation Foreign body exclusion robot Robotic Manipulator Robot Arm

Product principle

The high-precision laser camera is used to scan the ore and sundries on the track, accurately identify the ore and sundries therein, and give the position and height and other data, accurately control the manipulator to grasp the sundries and put them into the sundries collection box.

1: AI artificial intelligence image processing technology is adopted, with high image recognition rate. Newly emerged foreign object pictures can be added at any time for training

2: The specially developed mechanical arm is faster and more flexible, which can effectively adapt to various conveying speeds

3: It can read the horizontal and vertical coordinates of foreign objects, and can also accurately output the height coordinates of foreign objects and surrounding ores, so as to prevent the mechanical arm from overloading when grasping

4: High intelligence, unattended, optional remote monitoring

Technical advantages

1: The self-developed system is used for image enhancement, data coding, transmission, data smoothing, edge sharpening, segmentation, feature extraction, recognition and understanding and other related contents through image processing technology, which greatly improves the visual effect of images and optimizes computer analysis, processing and recognition of images. No matter whether the sundries are crushed, twisted or blocked, the robot can identify them and accurately grasp the sundries from the conveyor belt to the collection box/waste belt line.

2: The tracking module matches the visual processing results and the operation of the external conveyor line to dynamically track, realize the seamless connection between the machine and the vision, and improve the overall sorting accuracy.

3: Powerful data migration learning technology enables rapid deployment of intelligent robot sorters in different scenarios.

4: Six axis industrial robot, which optimizes the acceleration and deceleration performance of the robot hand, minimizes the working cycle time of the robot, is small, agile and has better flexibility.

5: The equipment is made of sturdy and durable materials, with strong reliability, long maintenance cycle, high protection level of the whole equipment, and is suitable for dust, high temperature, humidity and other harsh environments. It is also suitable for applications with high working intensity, harsh environment, high sorting accuracy and high consistency requirements.

6: High degree of intelligence, unattended, remote monitoring.

The machine body mainly includes 6 parts:

1: Robot, can be configured more than one, Multiple robots can be configured according to the capture time.

2: Control cabinet, including robot control box and PLC control cabinet

3: Visual acquisition, including lens, light source and control box

4: Algorithm IPC, UPS

5: Remote operation platform/dispatching room monitoring, including video monitoring, remote HMI, etc. (This function is optional)

6: Guardrail, including safety door interlock and mechanical arm emergency stop control (optional).

Technical Parameter

|

Structure |

6-axis industrial manipulator+deep learning control platform |

|

Sorting range |

stones, wood blocks, plastic bottles and other sundries |

|

Camera brand |

Mingde |

|

Recognition principle |

deep learning neural network, and modeling of foreign objects extracted as required |

|

Grab |

quick change bionic mechanical claw |

|

Power supply |

industry 380V, three-phase five wire |

|

Air supply |

>0.5MPA |

|

The grabbing capacity |

Manipulators shall be configured according to the maximum weight of objects to be grasped on site |

|

Belt speed |

>1.3 m/s |

|

Belt speed |

<1.8 m/sec |

|

Track width |

<2500mm |

|

Power supply |

380V,Three-phase five-wire. |

|

Air supply |

>0.5MPA |

|

Total Weight |

850kg |

|

Dimension |

2350×1100×2000 |

|

Gripping Diameter |

≥1CM |

|

Protective level |

IP65 |

|

Vision system |

CRM-CNN |

|

Rated power |

6KW(single robot configuration) |

Application fields

It mainly serves for the sorting of anchor bolts, steel drills, rags, wood, iron pieces, waste filling pipes and other sundries in the ore sorting, ore production and transportation process, replacing manual sorting, laying the foundation for reducing personnel and labor, reducing equipment failure rate, and reducing staff and increasing efficiency.

Tags :