Factors affecting the sorting effect of ore color sorter

Jan 03, 2023

Factors affecting the sorting effect of ore color sorter

Jan 03, 2023

Factors affecting the sorting effect of ore color sorter

For the ore color sorter, I believe most mining enterprises have long been familiar with. So, ore color sorter in the process of widely used in the mining industry sorting work, whether it can meet the needs of all customers, its sorting effect by which factors determine or influence it, Mingde photoelectric after a long-term use of our ore color sorter customer analysis, for different materials, different enterprises, we summarized some of the content.

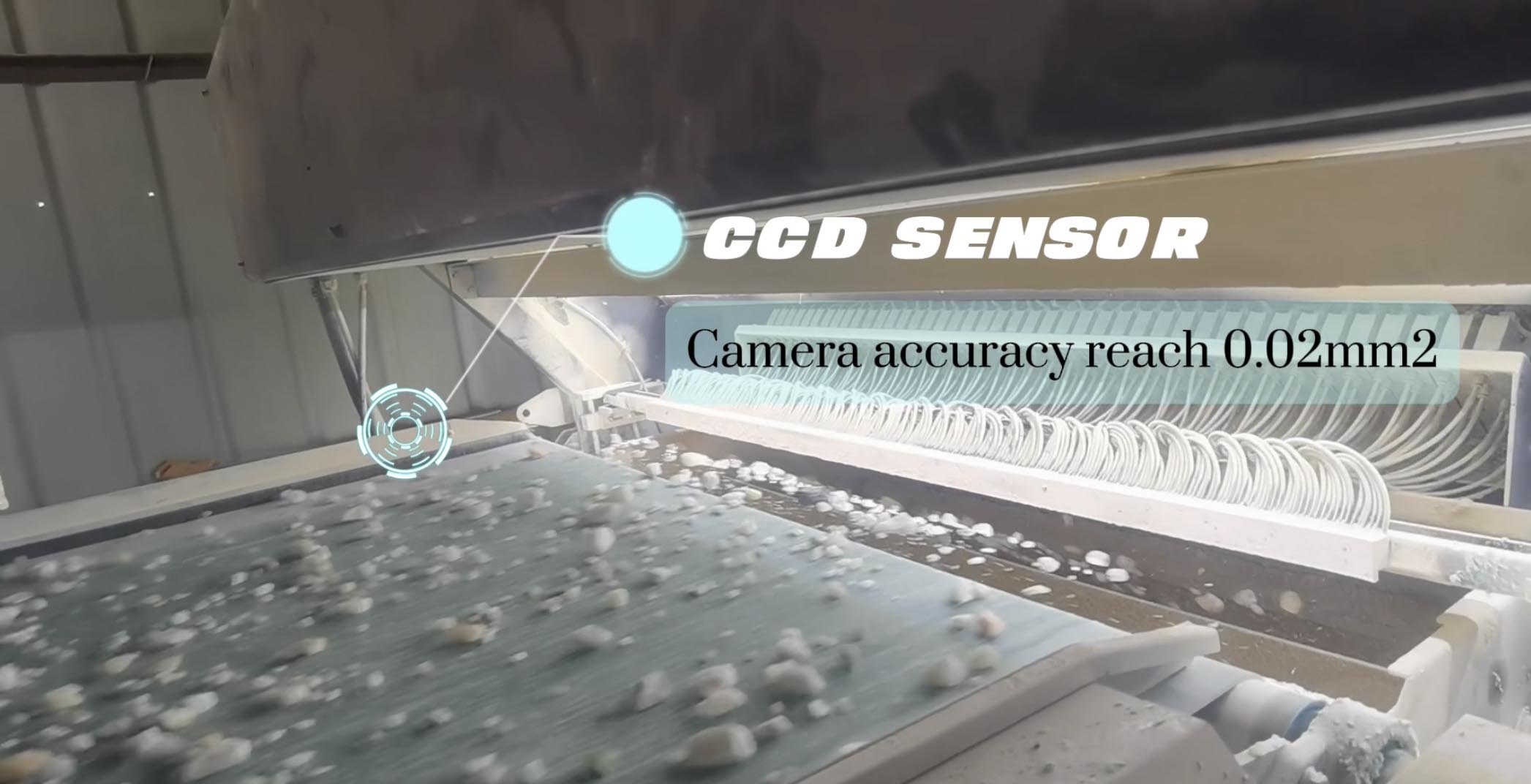

We often say, ore color sorter is a new automatic equipment, some people say ore color sorter is a kind of "robot", usually, ore color sorter mainly by the feeding system, photoelectric system, control system and sorting system four system composition. As a kind of ore sorting automation equipment, and weigh the four systems and judge the value of its work or mainly depends on the ore color sorter color sorting accuracy, processing capacity, raw materials containing impurities, selection of net rate and other factors.

In the actual production process, these factors are one, there are mutual influence and constraints of the relationship, must be examined at the same time. Our company (Mingde photoelectric) developed a new ore color sorter, in the software upgrade and spray valve response speed to meet the case at the same time, the servo system movement speed, the highest speed of the conveyor belt and the purity of raw materials will affect the color separation accuracy and the size of the processing capacity per unit of time; In addition, some manufacturers in the actual sorting process, the bad material cycle sorting, greatly reducing the rate of finished ore, in the effective time The efficiency of the qualified products is reduced within the effective time, which leads to the increase of the take-out ratio. If the take-out ratio is set too high, it will affect the selection rate and processing capacity of these two indicators; if set too low, the selected waste contains too much normal material, will cause waste. In a comprehensive manner, improve the sensitivity, the better the color separation effect, the greater the belt-out ratio; and the output requirements are also a direct impact on the color separation effect and belt-out ratio.

Therefore, after analysis, we have increased the track speed of the color sorter. Compared with other manufacturers, our crawler speed is several times of the same industry manufacturers. They want to improve the output, in can not solve the track speed problem, can only increase the material coverage, in the field production, such coverage will seriously reduce the effective distance between the materials, in the sorting will reduce the resolution, resulting in a lot of bad material "escape", therefore, such a way will only make the material to increase the take-out ratio, and further reduce the separation rate. More reduce the net selection rate. In the long run, for our mining manufacturers, simply can not meet the production requirements, let alone recover costs and increase efficiency.

If you can not achieve the expected color separation effect, in addition to improper debugging, there is a little influence is the rate of raw material impurities. Low rate of impurities, impurities between the interval is large, leaving the servo system response time is long, you can also increase the speed of the conveyor belt to improve production. Similarly, the higher the initial purity of the raw material, the less impurities, the higher the accuracy of color selection, the higher the accuracy, the higher the yield. The normal materials and defective materials in the raw materials must exist a certain color difference; the smaller the color difference, the more difficult the color separation, the worse the performance index, the election rate of materials of different colors is also different.

The factor that has the greatest impact on the quality is the problem of color separation accuracy, we know that the high requirements for the finished material is generally to achieve high precision color separation. For example, we take quartz sand as an example, if it is used to make quartz plates, it can not be sloppy, quartz sand for quartz plates must be high purity, quartz sand can not have a little yellow skin on the surface, the hardness of the stone should also be good, so that the quartz plates made to meet the standards of the industry. In addition, high-end quartz used for export, manufacturing wafers, aerospace business, etc. requires even higher quality products. Conversely, quartz used as a filler in general glass, paint, rubber, plastic, etc. is not as demanding. A certain doping rate does not affect the application, so the yield can be pursued appropriately.

Color sorter as a typical optical-electro-mechanical integration system, involving optical-electro-mechanical soft innovation and application in various fields, the speed of upgrading is very fast, is a typical innovative technology products, mining enterprises in the use of caution, to do a full understanding of the color sorter manufacturers, the color sorter operation of in-depth understanding, so that it plays a due investment benefits.

How to separate calcium carbonate with optical ore color sorting machine?

Jan 12, 2024

How to separate calcium carbonate with optical ore color sorting machine?

Jan 12, 2024

Mingde photoelectric ore color sorter to solve the ore sorting problem

Dec 08, 2022

Mingde photoelectric ore color sorter to solve the ore sorting problem

Dec 08, 2022

How to sort Associated non-metallic fluorite

Dec 29, 2022

How to sort Associated non-metallic fluorite

Dec 29, 2022

In winter, what should be paid attention to the ore color separator?

Dec 29, 2022

In winter, what should be paid attention to the ore color separator?

Dec 29, 2022

Factors affecting the sorting effect of ore color sorter

Jan 03, 2023

Factors affecting the sorting effect of ore color sorter

Jan 03, 2023

What are the advantages of Mingde photoelectric intelligent ore color sorter?

Jan 06, 2023

What are the advantages of Mingde photoelectric intelligent ore color sorter?

Jan 06, 2023

The Structure of Ore Color Sorter

Jul 02, 2024

The Structure of Ore Color Sorter

Jul 02, 2024

How to Select A Suitable Photoelectric Ore Sorting Machine

Jul 11, 2024

How to Select A Suitable Photoelectric Ore Sorting Machine

Jul 11, 2024

How to Choose An Ore Color Sorter?

Aug 10, 2024

How to Choose An Ore Color Sorter?

Aug 10, 2024

The Importance of Raw Ore Sorting

Aug 17, 2024

The Importance of Raw Ore Sorting

Aug 17, 2024