Subscribe to our newsletter and always be the first to hear about what is happening.

What exactly is the use of optical sorting? What are the prospects for development?

Jun 02, 2023What exactly is the use of optical sorting? What are the prospects for development?

What is optical sorting? In which field is it mainly used?

Optical sorting is mainly based on the optical properties of the object. When the object passes through the photoelectric sorting equipment, a beam of light will be irradiated and these rays will be absorbed, reflected or transmitted by the object. Different materials react differently to light, so optical sensors can be used to detect the optical properties of the material. With the continuous progress of science and technology and the expansion of applications, photoelectric sorting machine has now been in the food, food, mining and other industries.

What is the photoelectric sorter?

Photoelectric sorting machine work is mainly based on the combination of optical and electronic technology, through the optical sensor will detect the light signal into electrical signals, through the electronic processor for analysis and processing, the processor will be based on preset parameters and algorithms, control the solenoid valve to the material impurities, foreign objects, bad products, etc. to separate. Thus improve the quality of products and reduce production costs, to achieve the purpose of sorting. For example, the separation can be identified according to the color, shape, texture, texture, luster, density and other characteristics of the sorted materials.

So, what are the prospects for the development of such machines as photoelectric sorting machines,how to efficiently optimise ore sorting ?

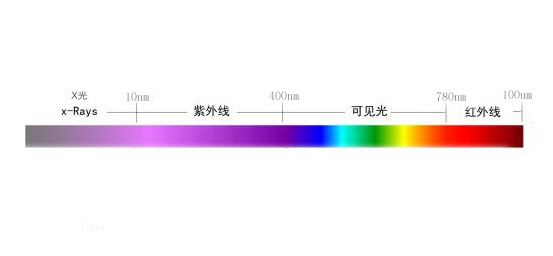

Mining sorting equipment ,Photoelectric sorting machine after nearly decades of development, according to the different characteristics of sorting materials, has developed X-ray, ultraviolet, visible light, infrared separation equipment in various wavelengths. According to the different application scenarios are mainly divided into grain color sorter, glass color sorter, ore color sorter, artificial intelligence sorter, ultraviolet color sorter, X-ray sorter, etc.

Photoelectric sorting equipment has been popularly used in grain and food, chemical industry, such as grain, fruit, glass, recycled plastic sheet, plastic particles, corn, various beans, various rice, ore, pepper, pepper, garlic rice, melon seeds, raisins, seeds, Chinese medicine, sea rice, shrimp skin, clove fish and so on. In ore sorting photoelectric beneficiation has become another emerging mainstream beneficiation method in addition to flotation, magnetic separation and re-election. It has been used in large quantities in common metals, non-metals, coal and other fields.

Let's really get to know the performance of photoelectric sorting machine below:

1、Sorting capacity

(1) photoelectric sorting machine as a photoelectric sorting equipment, its main purpose in the material to be sorted out impurities, foreign matter, bad products and other materials; can be sorted according to the material surface or density differences, for example, with color differences in materials can use color sorter; with a variety of color differences or other surface characteristics in addition to color differences in the use of artificial intelligence sorter; no features on the surface, internal specific features can be used X-ray intelligent sorting machine. All can be completed by a special sorting machine for a sorting.

(2) the sorting effect of the sorting machine with the material is directly related to the good or bad, such as 2% and 20% of the amount of impurities on the sorting machine can achieve the performance index is a great influence.

(3) Because some materials dissociation degree raw materials, resulting in the existence of companionship, so there is no 100% rejection rate.

2, objective evaluation of the yield, sorting effect and the relationship between the take-out ratio

The three indicators are interdependent and constrained relationship. Sorting equipment to adjust the sorting parameters, the better the required sorting effect, the greater the relative take-out ratio; yield will also affect the effect of sorting and take-out ratio, in the actual commissioning of the sorting, according to the site conditions and according to customer requirements for targeted optimization adjustment. To achieve maximum satisfaction. Several principles should be grasped:

(1) in the case of sorting effect can meet the requirements, maximize the rate of finished material; at the same time, in order to protect the service life of equipment spare parts, non-metallic ore is often used to blow less than the principle of blowing more.

(2) for ore sorting in the tailing content with the requirements of the ore, often use the way to blow concentrate to reduce the tailing content.

Pay attention to the sorting site situation, timely communication, understanding the needs.

3、The correct understanding of the ore sorting

Sorting is very different, there is no certain standard, so for different industries, different application scenarios, the best use of special sorting equipment. Although the working principle is the same, but the targeted direction is different, in the development of equipment, design, the choice of accessories will have targeted differences, the specific material selection of specific manufacturers, specific sorting equipment.

Grain or grain is best to use grain-type color sorter, ore sorting selection of ore color sorter or intelligent machine, such as professional R & D, production of ore photoelectric sorter of the name of the German photoelectric, in the field of ore, especially unique technical advantages and sorting equipment.